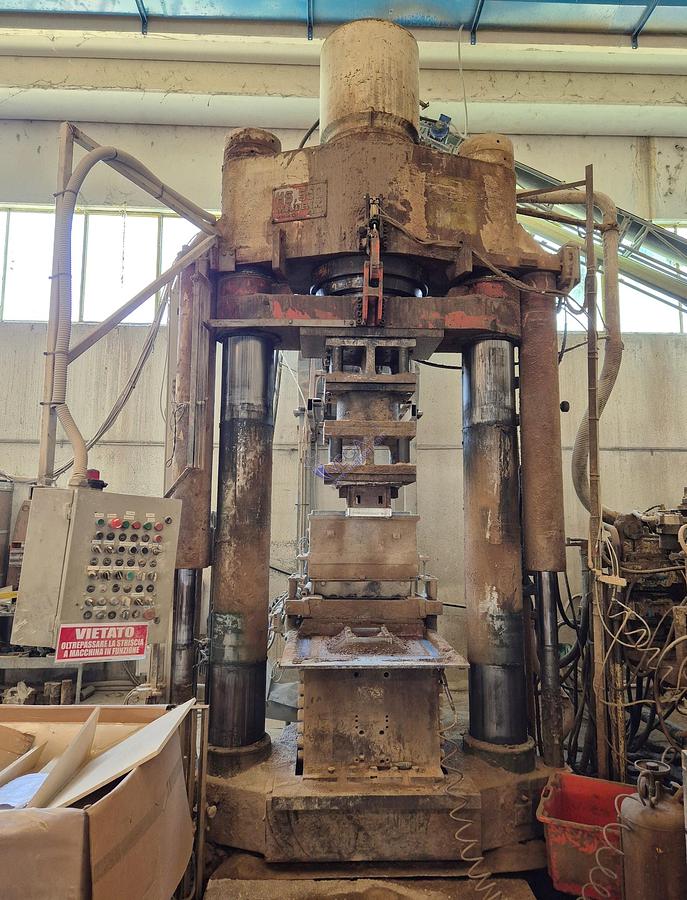

Pressa idraulica a secco per materiali refrattari MATRIX mod. HS.550 - doppio pistone (pressata dall'alto e dal basso) per pressatura refrattario, potenza massima di pressata 550 Ton

Pressa idraulica a secco per materiali refrattari MATRIX mod. HS.550 - doppio pistone (pressata dall'alto e dal basso) per pressatura refrattario, potenza massima di pressata 550 Ton

Posizione:Caldogno, Italia

Descrizione

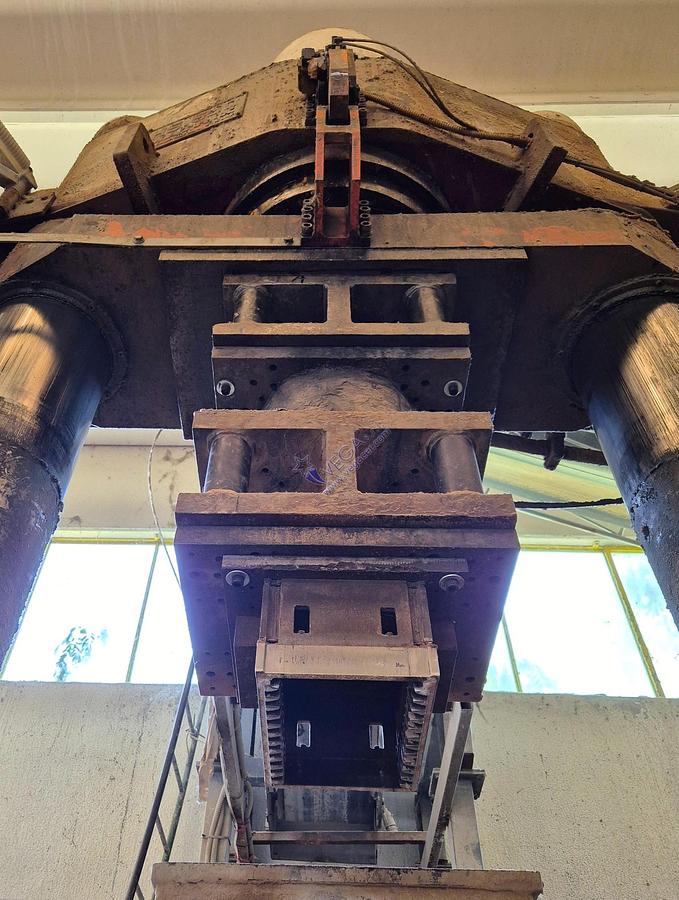

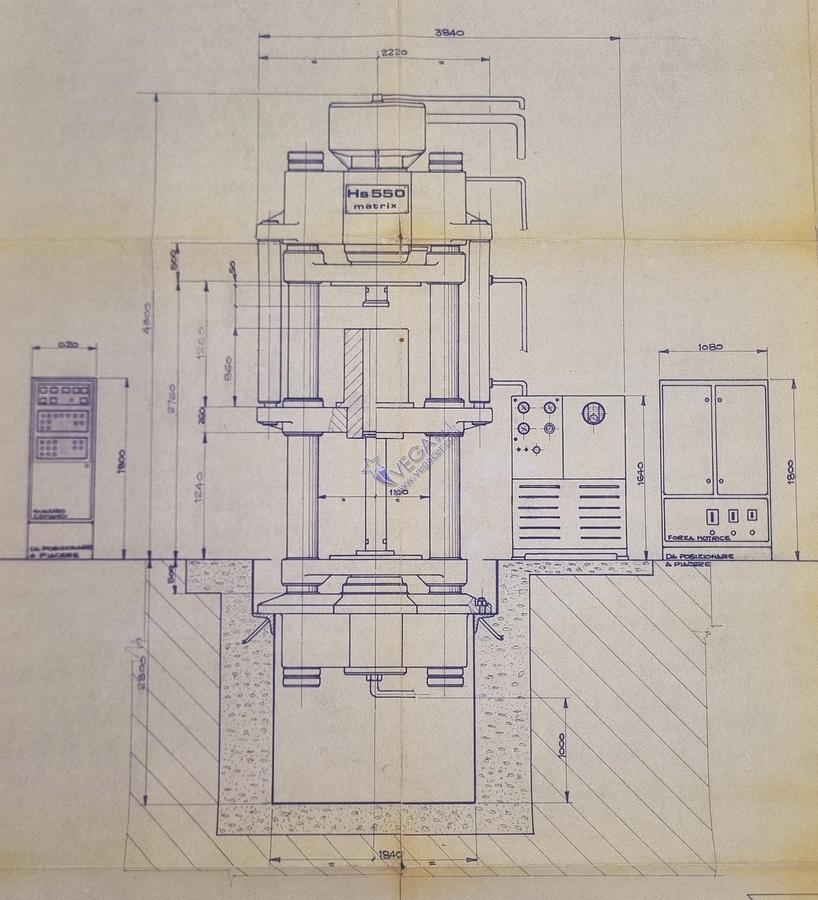

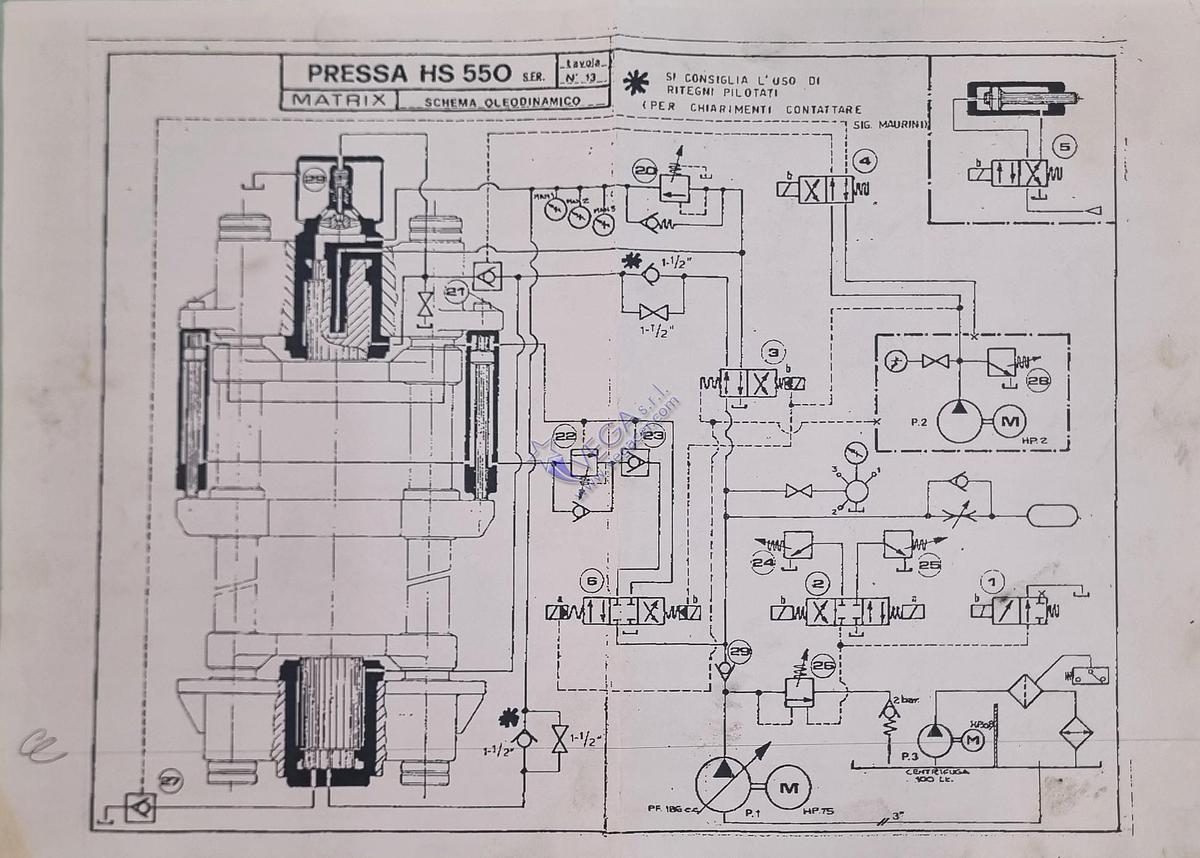

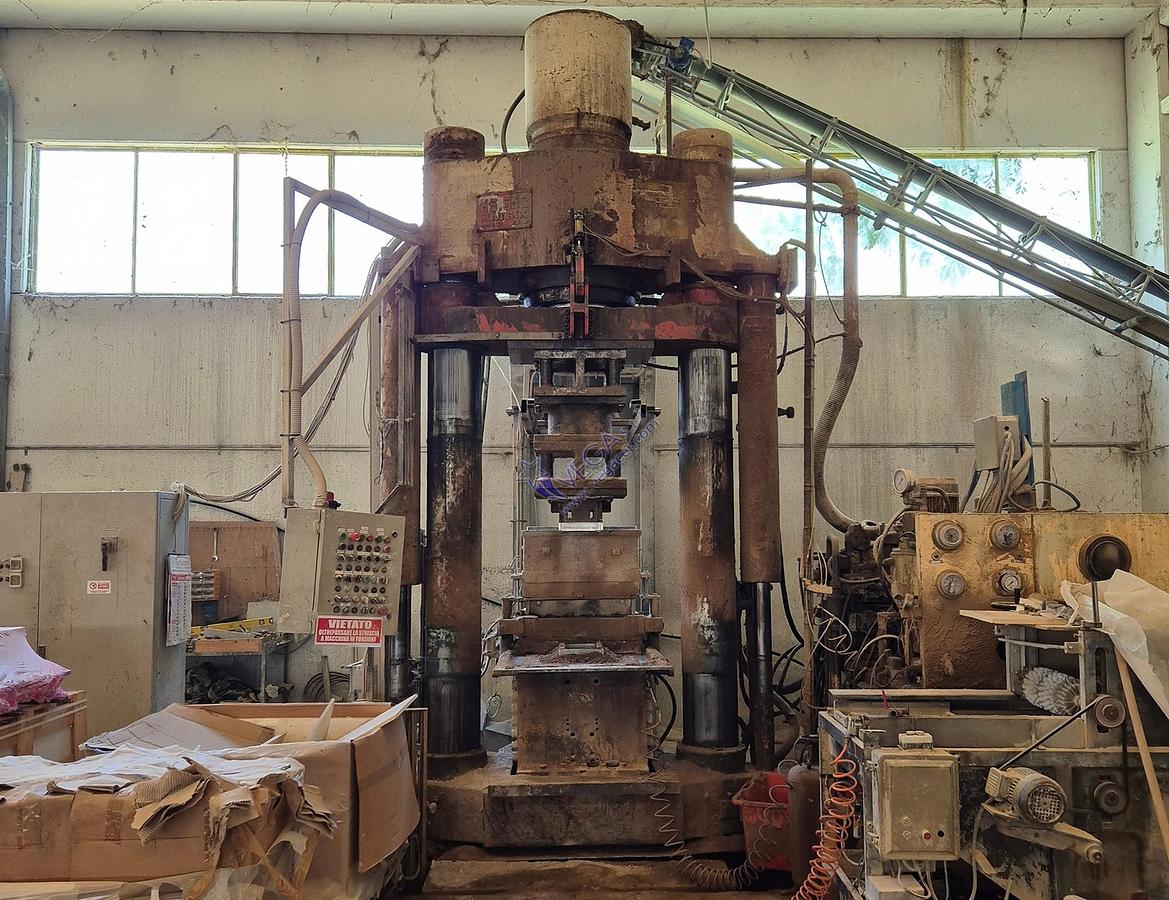

La pressa idraulica MATRIX HS.550 è una macchina potente e precisa, progettata per la produzione di materiali refrattari. Grazie al suo sistema a doppio pistone, con pressata contemporanea dall’alto e dal basso, garantisce una compattazione uniforme e un’eccellente qualità del prodotto finito. La pressa sviluppa una forza massima di pressata di 550 tonnellate, rendendola ideale per applicazioni refrattarie gravose.

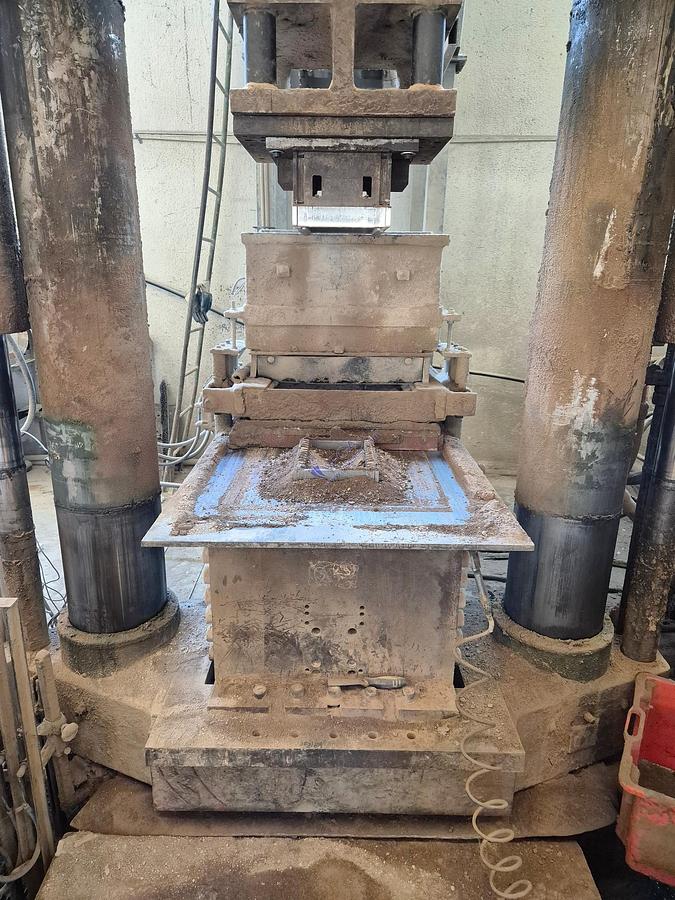

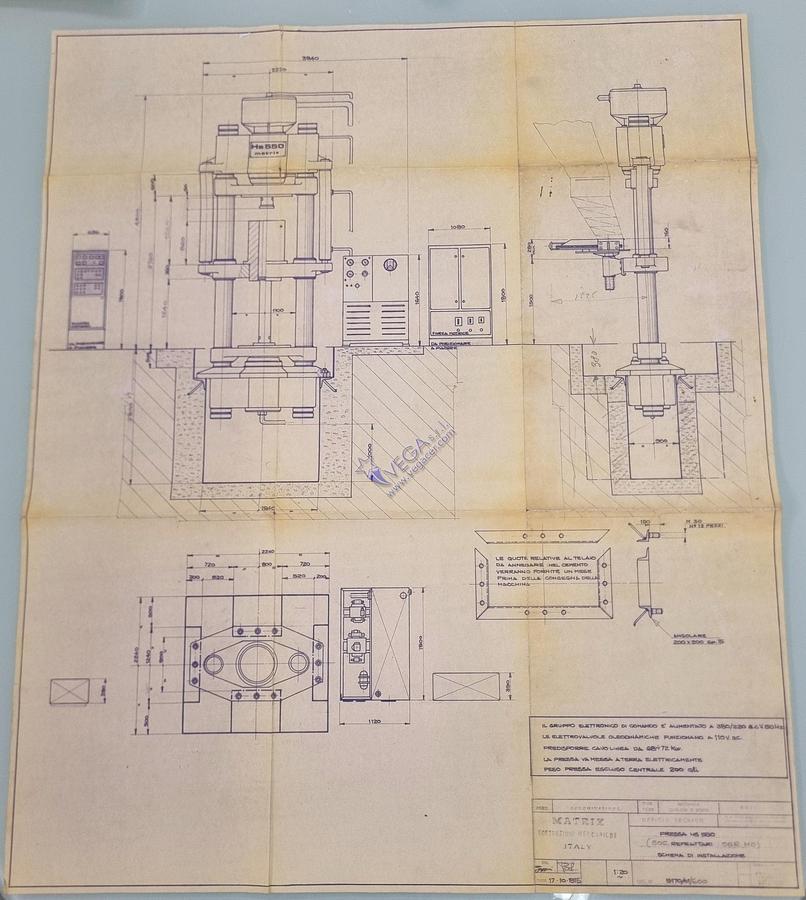

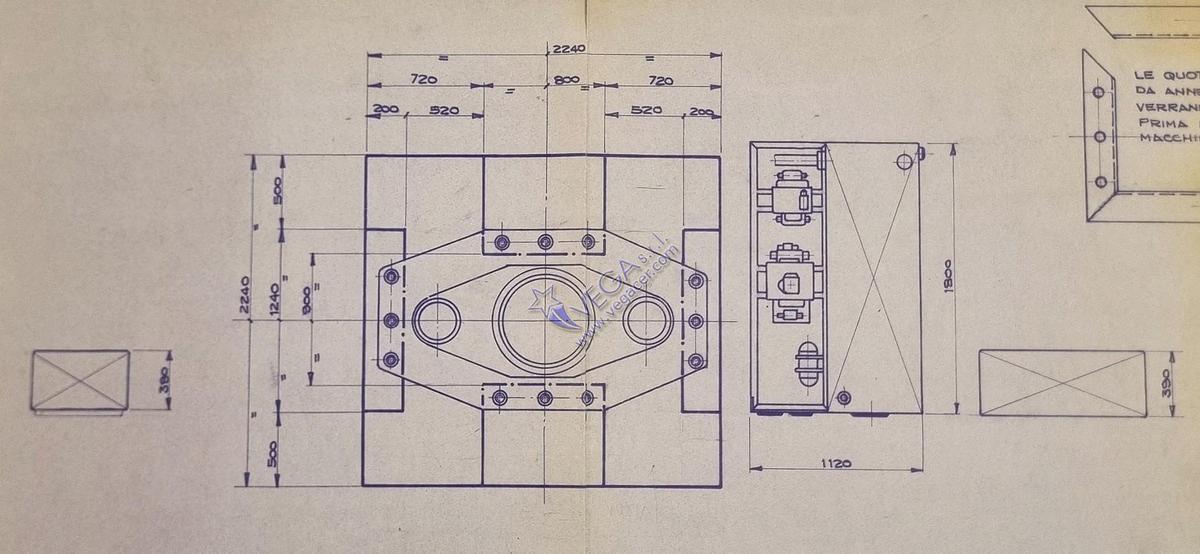

L’area di lavoro offre dimensioni generose, con uno spazio utile di 2760 mm tra il piano di lavoro e la traversa superiore e 1100 mm tra le colonne. Il piano di lavoro misura 950 x 1000 mm, offrendo ampia flessibilità per stampi di varie dimensioni.

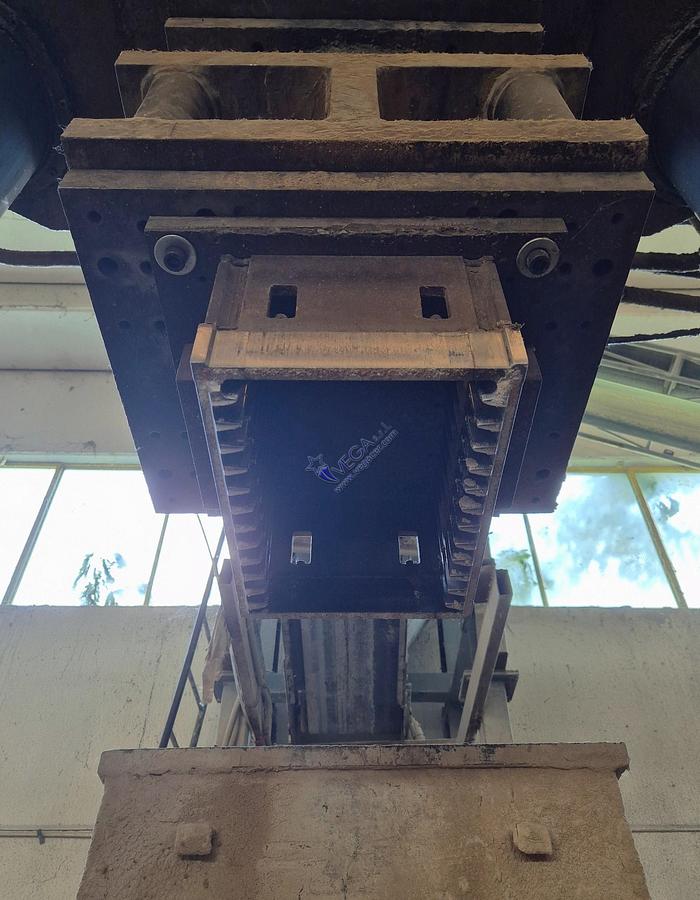

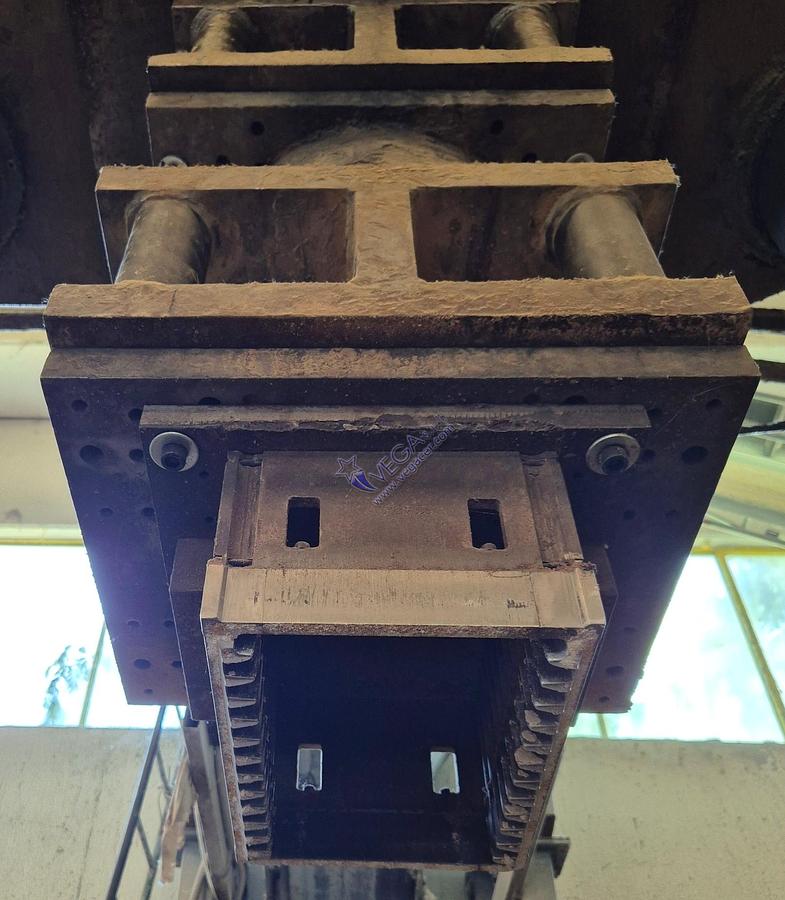

La pressa è dotata di un sistema automatico di carico e scarico, che aumenta la produttività riducendo i tempi di movimentazione. Attualmente monta uno stampo per cassette refrattarie da 20 x 20 cm con 11 alloggi, adatto a produzioni industriali su larga scala.

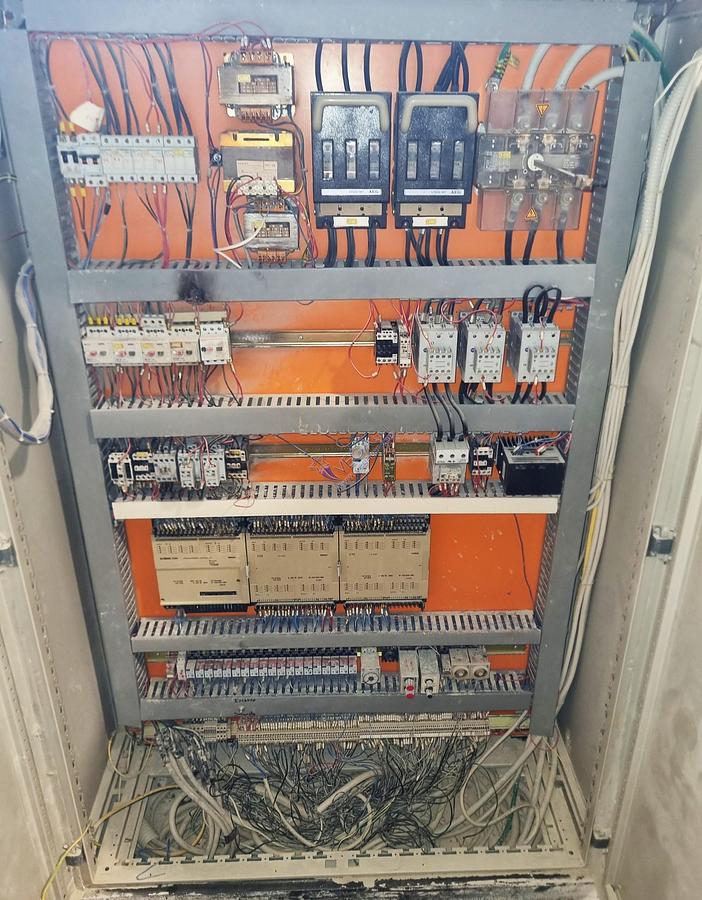

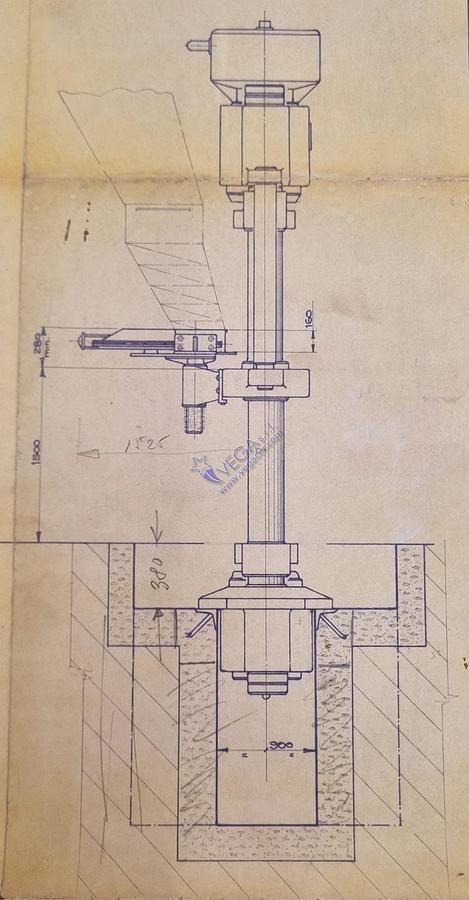

La macchina funziona con alimentazione elettrica 400 V / 50 Hz trifase ed è completa di centralina idraulica, tramoggia di carico con nastro e quadro elettrico. Nella configurazione installata, presenta dimensioni complessive di 4000 x 3300 (+1000 tramoggia di carico) x 4600 mm, con una buca di 2300 mm. Nonostante la sua elevata potenza, la pressa è progettata per garantire affidabilità e continuità di esercizio negli ambienti produttivi più esigenti.

Specifiche

| Produttore | MATRIX |

| Modello | mod. HS.550 |

| Condizione | Usato |

| Numero di magazzino | 7984 |

| Tipo pressa | pressa a secco per materiali refrattari |

| Sistema di pressata | dall'alto e dal basso contemporaneamente |

| N° pistoni | 02 |

| Pressata massima Ton | 550 |

| Tipo di sistema di carico/scarico | automatico |

| Spazio utile tra il piano di lavoro e la traversa superiore mm | 2760 |

| Spazio utile tra le colonne mm | 1100 |

| Dimensioni piano di lavoro (larghezza) x (lunghezza) mm | 950 x 1000 |

| Tensione Volt / Frequenza Hz | 400/50 |

| Fase | trifase |

| Peso della pressa Kg | 2000 |

| Dimensioni buca (larghezza) x (lunghezza) x (altezza) mm | 1840 x 900 x 2300 |

| Dimensioni d'ingombro centralina idraulica (larghezza) x (lunghezza) x (altezza) mm | 2350 x 1350 x 1500 |

| Dimensioni d'ingombro quadro elettrico (larghezza) x (lunghezza) x (altezza) mm | 1200 x 500 x 1900 |

| Dimensioni d'ingombro pressa idraulica (larghezza) x (lunghezza) x (altezza) mm | 2600 x 2400 x 4600 (+2300 della buca) |

| Dimensioni d'ingombro tramoggia di carico con nastro (larghezza) x (lunghezza) x (altezza) mm | 2100 x 1200 x 4400 |

| Dimensioni d'ingombro unità di pressatura completa quando installata (larghezza) x (lunghezza) x (altezza) mm | 4000 x 3300 (+1000 loading hopper) x 4600 |

| Stampo montato attualmente | stampo per casella refrattaria con dimensioni 20 x 20 cm e n°11 alloggi |