MICROPROCESSORS AND THERMOREGULATORS FOR KILNS AND FURNACES

We supply and give support on Pixsys thermoregulators and microprocessors.

They are extremely precise and reliable, with software dedicated to ceramic kilns and not only. Widely tested and sold all over the world, they are installed by the main and most well-known kilns and furnaces manufacturers. They all have multi-voltage power input from 24 to 230V AC/DC and are compatible with all the main types of thermocouples.

ATR 171

ATR 171 thermoregulator 72x72mm format, with dual 4-digits display for high visibility in the industrial environment, distinguished by high configurability. Two inputs can be programmed for a wide range of sensors. Power supply range from 24 to 230V AC/DC. The digital input allows external activation of various functions, including the Timer for delayed start or timed control.

ATR 243

ATR243 thermoregulator represents the top of the range and is the most versatile model of controllers in the 48×48 mm format (1/16 DIN). The functions of the ATR243 software include the PID hot-cold control algorithm, open-close logic for valve control, programming of a control cycle (mini cycle up to 3 step – slow raise / direct raise / temperature holding time ), maximum current threshold alarm.

ATR 902

ATR 902, designed for the automation of hobby and professional kilns for ceramics, glass or laboratory applications, allows the programming of 15 cycles/programs that can provide up to 18 steps/segments, all of which can be configured by the user as raise/maintain/lower. Being a detachable hand microprocessor it is very useful for Schools, to prevent unauthorized use of the kiln.

ATR 421

ATR 421 is a microprocessor 48x96mm (1/8 DIN), single control loop. Allows the programming of 15 cycles/programs that can provide up to 45 steps/segments, all of which can be configured by the user as raise/maintain/lower. Programming mode of the work cycle that is intuitive and simple to use even for inexpert operators. MEMORY-CARD or parameter setting software help the installer configure the device quickly and easily.

ATR 621

ATR 621 microprocessor is the most widely used microprocessor in electric kilns. Format 72x72mm, single control loop. Allows the programming of 15 cycles/programs that can provide up to 45 steps/segments, all of which can be configured by the user as raise/maintain/lower. Step end wait software functions (in case of a delay of the process on the programmed setpoint value) and Cycle Recovery mode (after a power cut-off) are the main features of this microprocessor.

KTD

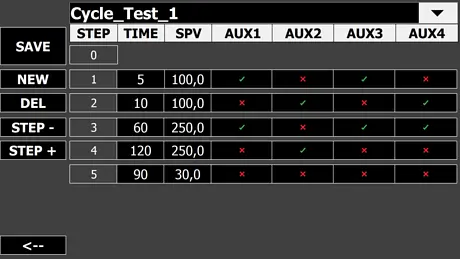

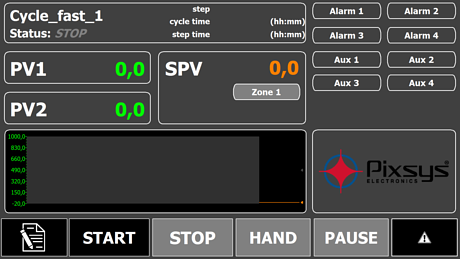

The KTD system is dedicated to the management of electric/gas kilns and

industrial dryers, allowing PID control + adaptive Auto-tuning of up to

8 zones. Each zone can follow its own control loop according to the

construction characteristics of the kiln.

The software is fully

parameterizable and integrates the functions typically required for heat

treatment plants, including automatic cycle recovery in case of power

failure, end-of-step waiting in case of delays/inefficiencies, control

of the process difference between zones, and delayed/programmed cycle

start.

The KTD710 and KTD810 kits make available advanced features that meet the requirements of Industry 4.0 :

-

VNC and HTML5 WebServer services for remote control, even from a PC

outside the company network, via VPN created by

PixsysPortal service;

- Energy consumption monitoring using the optional EnergyMeter 2100.35.032;

- Reports of executed cycles exportable in CSV format via USB key or via FTP.

- Furnace status sharing via ModbusTCP for easy integration with company MESs.

The

kit consists of a 4'' (KTD410), 7'' (KTD710) or 12'' (KTD820)

touchscreen operator panel and a variable number of DRR460 PID

controllers, combined with one or two MCM260X-4AD digital I/O modules .