De-airing pugmill LAKER mod. LV 250B.1

De-airing pugmill LAKER mod. LV 250B.1

Location:Caldogno, Italy

Description

The de-airing pugmill LAKER mod. LV 250B.1 is designed to ensure high-quality mixing and de-airing of ceramic bodies. It features two 250 mm screws working together with a speed adjustment system via inverter (functionality to be verified), delivering stable and efficient extrusion performance.

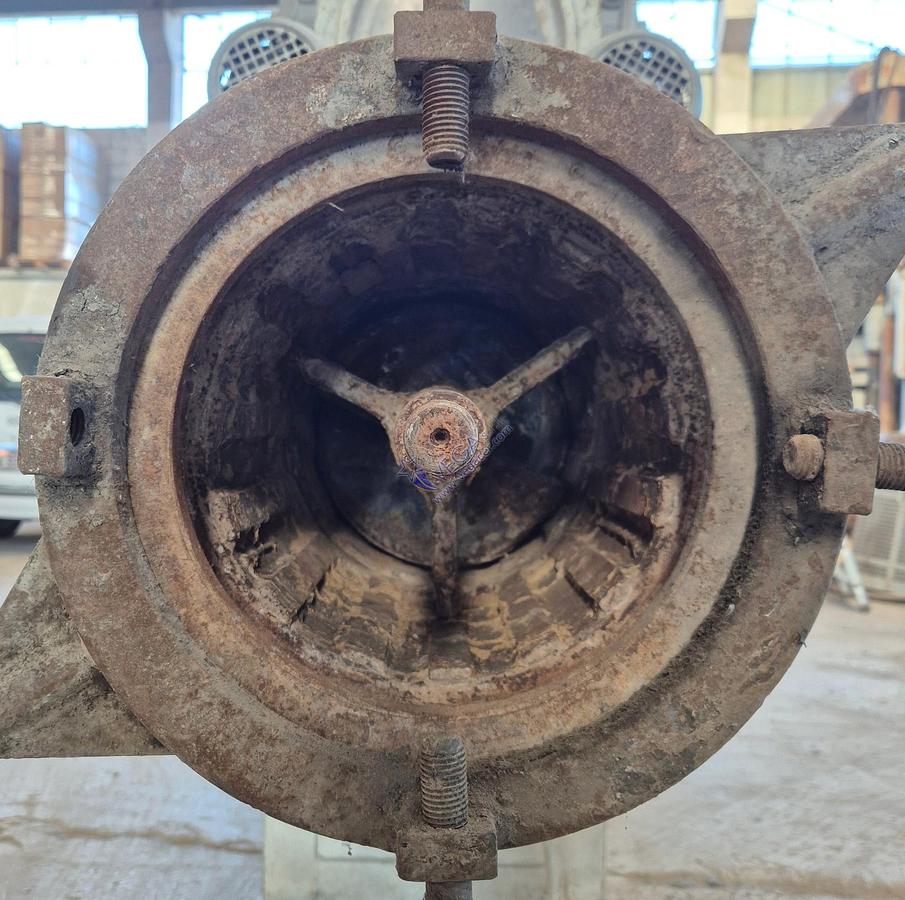

It is equipped with a cylindrical die-holder mouth with bayonet lock system, with a 250 mm barrel at the screw outlet, allowing the use of multiple die configurations.

The degassing process is managed through an oil vacuum pump, while the operating force is guaranteed by 13.2 kW and 30 kW screw motors, along with a 3 kW vacuum pump, powered at 400V / 50Hz three-phase.

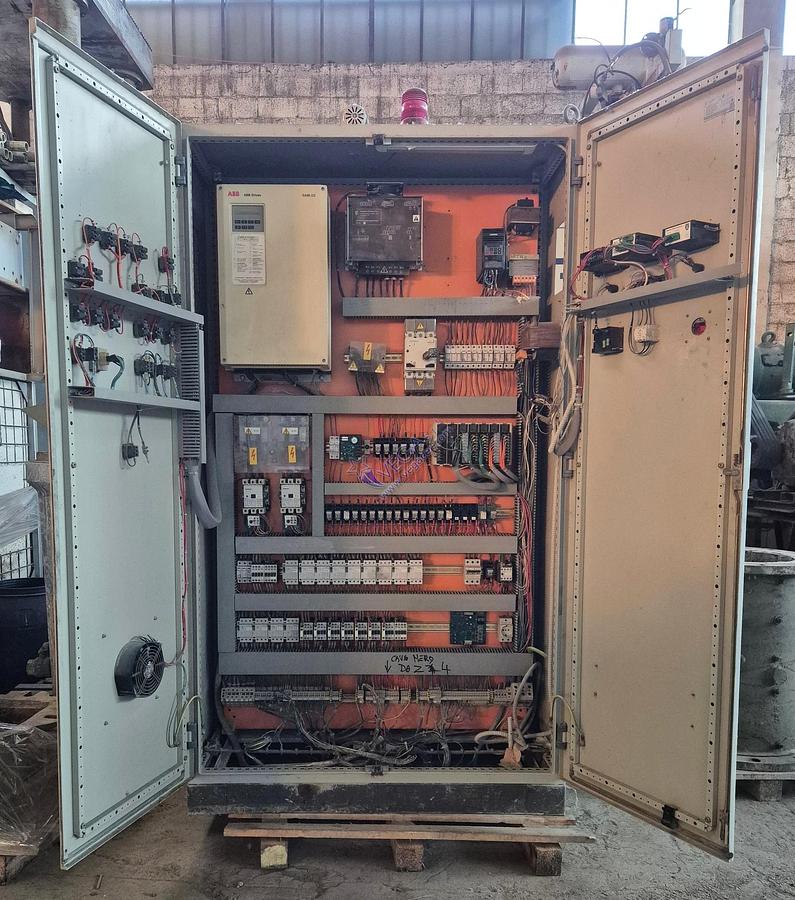

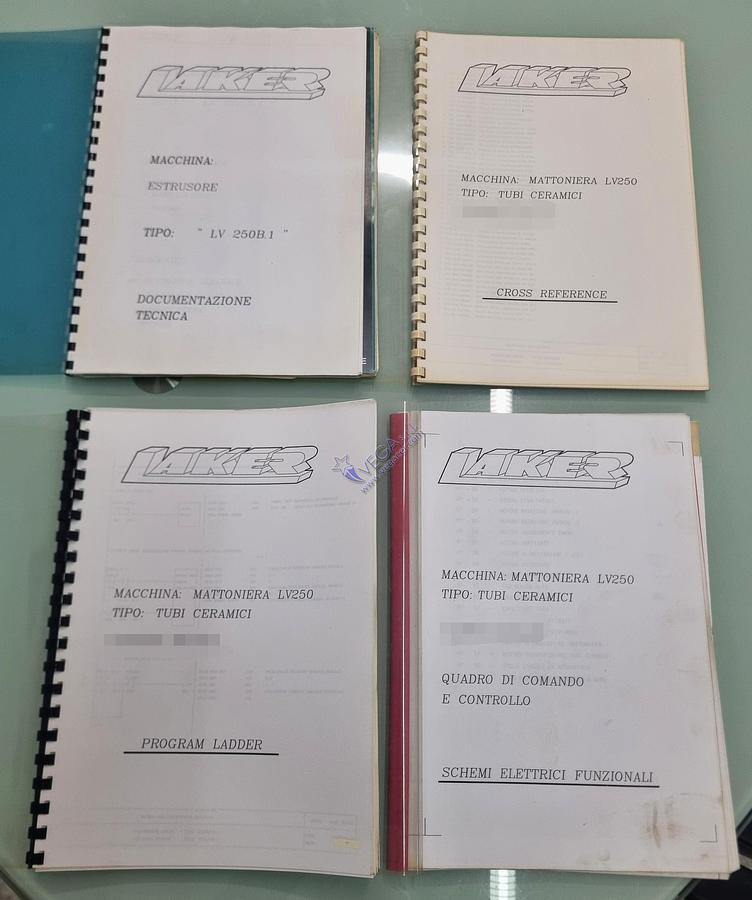

The machine an be installed within overall dimensions of 1380 x 3710 x 2260 mm, while the additional components require separate space: the electric switchboard measures 1200 x 550 x 2250 mm, and the vacuum unit 1300 x 450 x 1570 mm. The system is also complete with technical documentation.

Please note: the mixing chamber must be completely emptied before use, as the material currently inside is dry.

Specifications

| Manufacturer | LAKER |

| Model | mod. LV 250B.1 |

| Condition | Used |

| Stock Number | 8010 |

| N° of screws | 02 |

| Diameter of screws mm | 250 |

| Complete of device to reduce the screws speed | YES |

| Type of device to reduce the screws speed | inverter (functionality to be verified) |

| Type of extrusion mouth | cylindrical die-holder mouth with bayonet lock system |

| Cylindrical barrel from end of screw diameter mm | 250 |

| Complete of vacuum pump | YES |

| Vacuum pump type | oil vacuum pump |

| Higher screw motor power kW | 13,2 |

| Lower screw motor power kW | 30 |

| Power vacuum pump kW | 3 |

| Tension Volt / Frequency Hz | 400/50 |

| Phase | three phases |

| De-airing pugmill overall dimensions when installed (width) x (lenght) x (height) mm | 1380 x 3710 x 2260 |

| Electric switchboard overall dimensions (width) x (length) x (height) mm | 1200 x 550 x 2250 |

| Vacuum pump overall dimensions (width) x (lenght) x (height) mm | 1300 x 450 x 1570 |

| Complete with technical documents | YES |

| Please note | Before use, the de-airing pugmill must be completely emptied as the material inside is dry |