Complete plant for the production of refractory material

Complete plant for the production of refractory material

Location:Caldogno, Italy

Description

!!! THE FOLLOWING LIST OF MACHINES CAN BE PURCHASED AS A COMPLETE PLANT OR INDIVIDUALLY, ACCORDING TO SPECIFIC REQUIREMENTS !!!

Medium-sized complete plant for the production of refractory material, through extrusion, casting and dry pressing.

The plant includes a full range of machines covering all stages of the process, from body preparation to final firing and product handling.

List of single machines part of the plant:

- Item number 7977 – Ventilated air static chamber dryer CM

- Item number 7978 – Gas turbo kiln JOB FORNI mod. PULSAR BRICK – 6 m³, 1450°C, brick lining

- Item number 7980 – Rectifying machine ARENA mod. LFM 4+1

- Item number 7981 – Automatic longitudinal multi-disk cutter TUNISI mod. LT251

- Item number 7982 – Semi-automatic transversal disk cutter ARENA

- Item number 7983 – Jib crane with STARTEK hoist

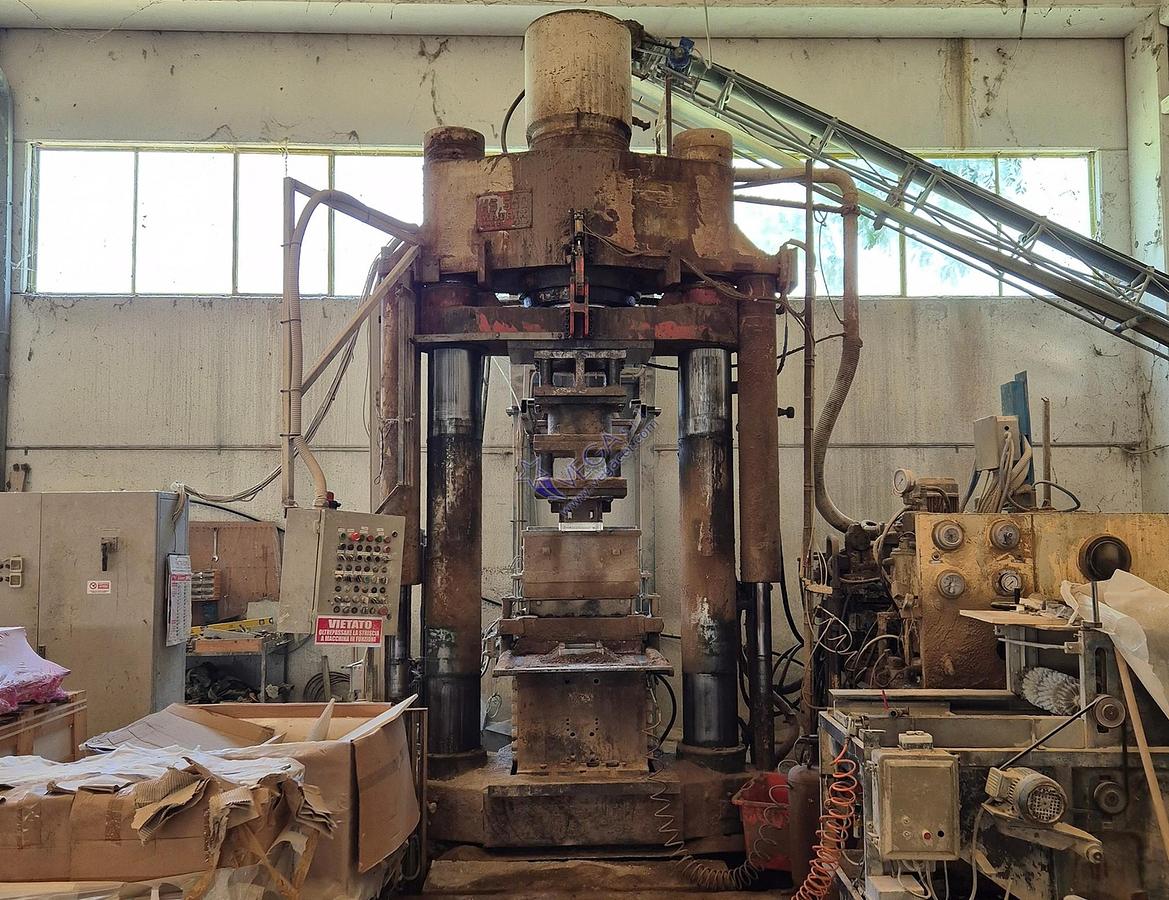

- Item number 7984 – Dry hydraulic press for refractory MATRIX mod. HS.550 – double piston (top and bottom pressing) for refractory pressing, max pressing force 550 Ton

- Item number 7986 – Extruder MORANDO mod. MVP 3 series D

- Item number 7987 – Double-shaft mixer MORANDO mod. MBAF 4

- Item number 7988 – Automatic vertical wire cutter for slabs OMG mod. TVP500E/A

- Item number 7990 – Slow agitator VICENTINI mod. LABOR 50 with tank

- Item number 7991 – Pan mixer with rotating tank

- Item number 7992 – Planetary mixer SIOME with rotating tank – useful tank capacity 1000 l

- Item number 7993 – Heavy trolleys for drying ceramic products

- Item number 7994 – Gas turbo kiln FICOLA – 22 m³, 1300°C

- Item number 7995 – Slow agitator VICENTINI mod. LABOR 50 with tank and vibrating sieve VICENTINI mod. 300 x 500

- Item number 7996 – Semi-automatic transversal disk cutter RAIMONDI mod. C.M. 150

Specifications

| Condition | Used |

| Stock Number | 8001 |